MAASTEK TECHNOLOGIES

Who We Are

Movers And Shakers

MAASTEK Technologies is a leading Solution provider of cutting-edge technologies and services, offering scalable solutions for businesses of all sizes. It provides innovative, high-performance RF/Microwave components and Front End Devices, Advanced LEDs for industries such as telecommunications, aerospace, and defense. Expertise in microwave design, advanced fabrication techniques, focus on quality and performance. Founded by a group of friends who started by scribbling their ideas on a piece of paper, today we offer smart, innovative services to dozens of clients worldwide. Why not join our fast growing client base? Get in touch today to learn more.

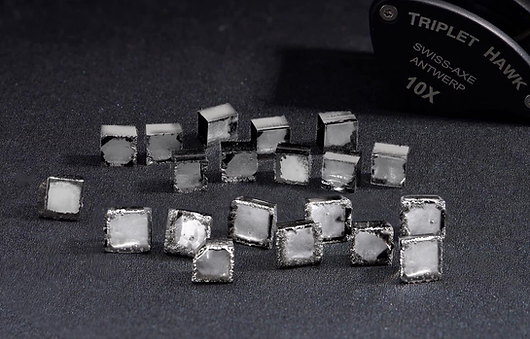

Lab-Grown Diamond MPCVD Machine developers with Technology

We Are The Company Founded In 2000. Since 2022 We Are Actively Engaged In The Innovation And Development of The MPCVD Diamond Growing Technologies in 6kw and 12kw. We Are On Our Front Foot To Bring The Latest Technological Solution To The Table That Can Match The Speed Of The Growth of Lab Grown gems & jewellery Industry.

We Are Aspiring Microwave Plasma CVD Diamond machine & Reactor Manufacturers. The Company Is Thriving To Mark Its Presence In The Industry As An Innovative And Cutting Edge Solution Provider In Terms Of Fulfilling The Requirement Of The Lab Grown Diamond Manufacturing Industry. With Our World-Class Advanced MPCVD Diamond Growing Machine. With The Help Of Creative Ideas And Transforming Technology, We Are Willing To Mark Our Presence As The Leading CVD Diamond Growing System Manufacturer.

Key features of our MPCVD system

At MAASTEK Technologies, We Have Designed And Developed MPCVD Machines That Are Providing The Best Outcome.

-

High Power Density Plasma

-

High Operating Pressure Up To 400 Mbar Or More

-

6 KW Microwave Generator (Switch Mode Power Supply)

-

4 Gas Lines (Additional Lines On Request)

-

2” Substrate Holder

-

Easy Substrate Loading / Unloading

-

Fully Automated Process

-

Low Maintenance

-

It can be achieved 5.5mm height in Single Run time and more can be reach in second Run.

-

Z-Mover” For single crystal growth with movement range up to 15mm and feedback speed adjustment.

-

Low Energy consumption.

-

One batch of crystal’s cycle period can be achieved in 22 days continuously

-

Effective long life period of Microwave Magnetron Head

-

Low Growing Cost.

Chamber and the substrate holder

Type - Coaxial cavity resonator

Chamber material –aluminum

Stage material - Molybdenum-shielded copper

Water cooling for chamber walls and stage

Visual control - 5 diagnostic 70 mm CF quartz windows Specialized molybdenum substrate holders

Microwave system

-

MW power supply - 6 kW, water-cooled

-

Magnetron - 6 kW at 2.45 GHz, water-cooled

-

Insulator - Circulator and dummy load, water-cooled

-

3-stub waveguide tuner, high-reliability and high-repeatability diamond deposition system capable of high growth rates for whole batch crystal diamonds processes in 22 days with 5.5mm height in single run time & In second run can be achieve up to 7+mm.

-

With its unique reactor and growing setup, it allows to build a high density and range plasma with high stability, during long-term operation. This key characteristic, as well as its high flexibility and intelligent design, allows the reactor to grow gem quality diamonds and with high production rates with good clarity.

-

To make this machine more efficient to others we have enabled it to be controlled and maintained with least human intervention for consistent results and superior quality growth. It is developed with unique process / recipe to produce diamonds of white colors with some additional process and high quality diamond (GHI) as grown without any additional process and get G Plus colors after HPHT Treatment.

Check our Gallery which is builtwith our experience